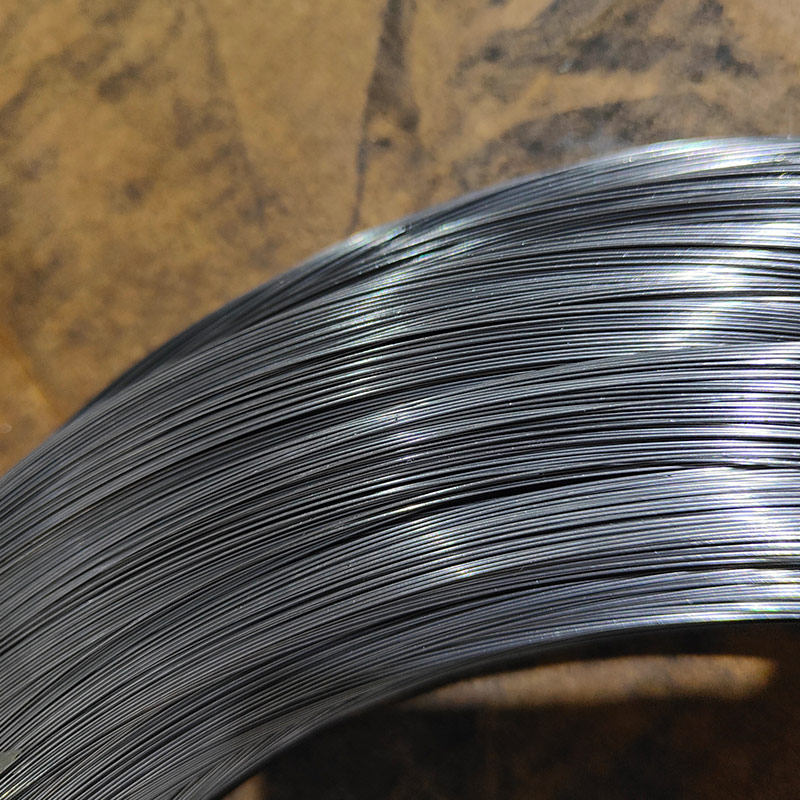

High Carbon Steel Spring Wire

High Carbon Steel Spring Wire is a kind of steel wire used to make spring (SPRING) or wire type (WIRE FORM). According to the different uses of the spring, there are various types of spring steel wires required for springs, such as spring steel wires for mattress springs (referred to as mattress steel wires) with lower requirements, spring steel wires for shock absorbers, and springs for suspension springs.

High Carbon Steel Spring Wires for engine valves and High Carbon Steel Spring Wires for camera shutters, etc. Although there is no unified standard classification name, the quality requirements of these wires are different. High Carbon Steel Spring Wire can also be classified according to the manufacturing process, such as raw-drawn spring steel wire (without lead bath quenching treatment before drawing), lead-quenched spring steel wire, galvanized spring steel wire, oil-quenched spring steel wire, etc.

High Carbon Steel Spring Wire Standard

The current national and industry recommended standards for High Carbon Steel Spring Wire are divided into two types:

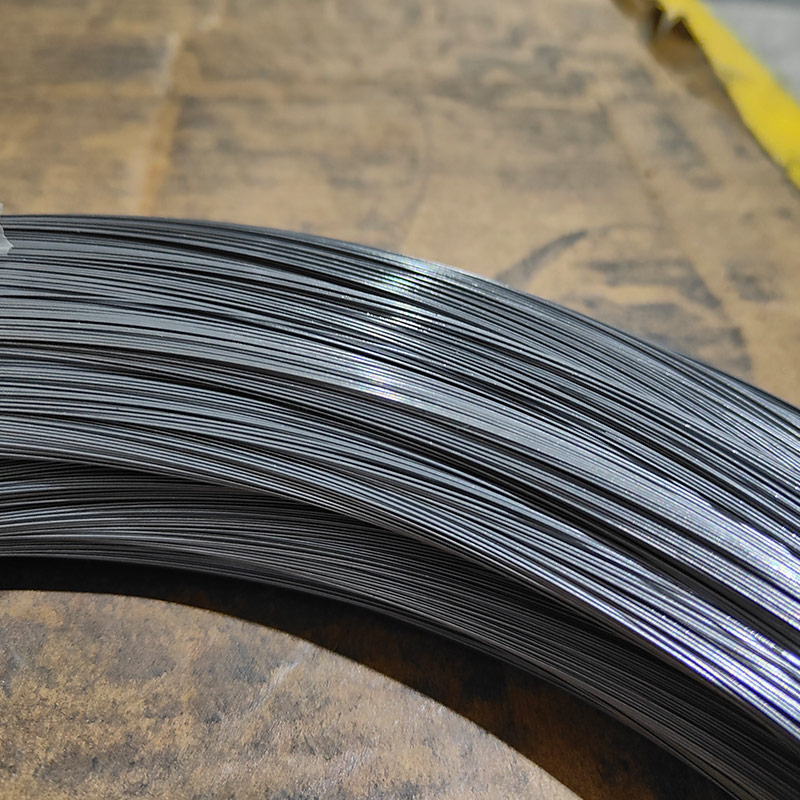

1. Cold-drawn High Carbon Steel Spring Wire

One is cold-deformed reinforced High Carbon Steel Spring Wire, also known as cold-drawn High Carbon Steel Spring Wire. The cold-drawn carbon spring steel wire is first quenched by lead to obtain a sorbite structure, and then the surface is phosphating, and drawn to the finished size with a large reduction rate. The steel wire structure is fibrous and has high tensile strength and elastic limit. , good bending and torsion properties. Cold-drawn High Carbon Steel Spring Wire has high dimensional accuracy, smooth surface, no oxidation and decarburization defects, and relatively stable fatigue life. It is the most widely used spring steel wire.

2. Oil quenched and tempered steel wire

Another type of carbon spring steel wire is martensitic reinforced High Carbon Steel Spring Wire, also known as oil quenched and tempered steel wire. High Carbon Steel Spring Wire can obtain good comprehensive mechanical properties through quenching and tempering treatment. When the wire size is small (φ≤2.0mm), the strength indexes of oil quenching and tempering steel wire are lower than those of cold-drawn steel wire after sorbitizing treatment. When the size of the steel wire is large (φ≥6.0mm), it is impossible for the sorbitized steel wire to use a large reduction ratio to obtain the required strength index, while the oil-quenched and tempered steel wire can be obtained as long as it is completely quenched. Steel wire for higher performance.

Under the same tensile strength, the martensitic reinforced steel wire has a higher elastic limit than the cold deformation reinforced steel wire. The metallographic structure of cold-drawn steel wire is fibrous and has obvious anisotropy. The metallographic structure of oil-quenched and tempered steel wire is uniform tempered martensite, which is almost isotropic. At the same time, the anti-relaxation performance of oil-quenched and tempered steel wire is better than that of cold-drawn steel wire, and the service temperature (150~190℃) is also higher than that of cold-drawn steel wire (≤120℃). In recent years, oil quenched and tempered steel wires of medium and large size have a tendency to replace cold drawn steel wires.

Typical Representatives of High Carbon Steel Spring Wire

The three spring steels 65, 70, and 85 are typical representatives of High Carbon Steel Spring Wire. The three spring steels have corresponding spring steel strips, spring steel plates, spring steel bars and spring steel wires. Their performance characteristics and uses are slightly different. It will be briefly introduced below.

After proper heat treatment, No. 65 High Carbon Steel Spring Wire can obtain high strength and elasticity, and also has certain plasticity and toughness, and is not sensitive to temper brittleness. Low hardenability, normalizing is generally used, and quenching-tempering is used for small-sized springs.

The strength and elasticity of 70 High Carbon Steel Spring Wire is slightly higher than that of 65 steel. The strength of 85 High Carbon Steel Spring Wire is higher than that of 70 steel, but the elasticity is slightly lower. 70 High Carbon Steel Spring Wire is suitable for the manufacture of small springs with small cross-sectional dimensions and low working temperature, and springs and elastic elements with low performance requirements and large cross-sectional dimensions.