Carbon Steel Wires

Carbon steel wire refers to prestressed steel wire with carbon content not exceeding about 0.9%. Most of the carbon steel wires used as prestressing bars in my country are high-strength steel wires and cold-drawn low-carbon steel wires. Increasing the carbon content (>0.9%) can improve the strength and hardness of the steel wire like cold work and heat treatment, but it will reduce its plasticity, toughness and weldability.

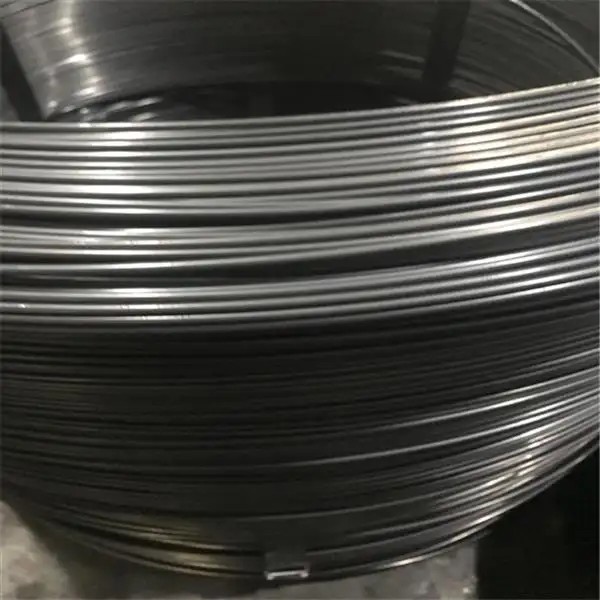

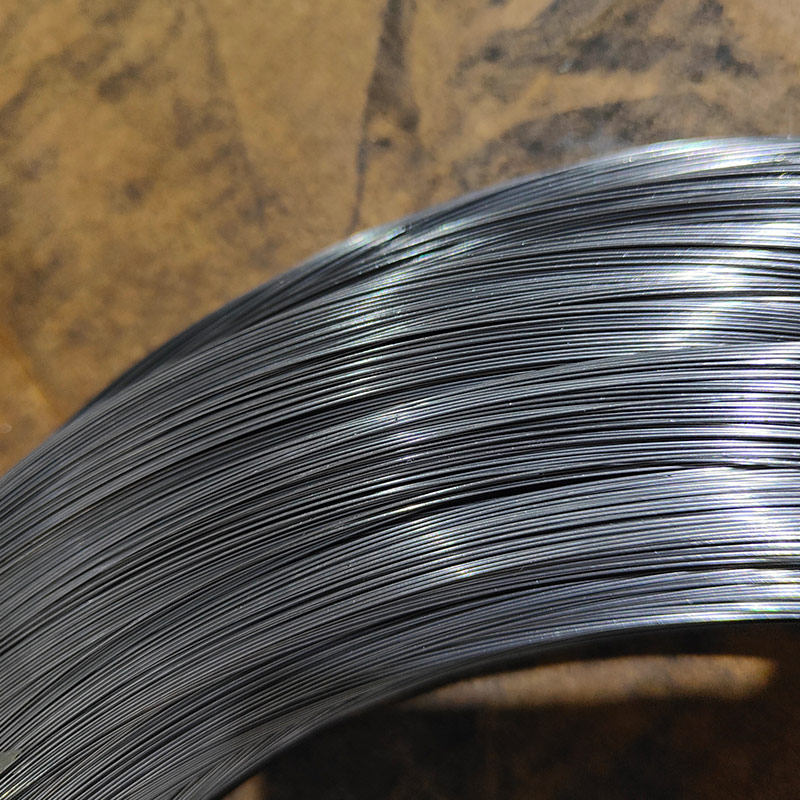

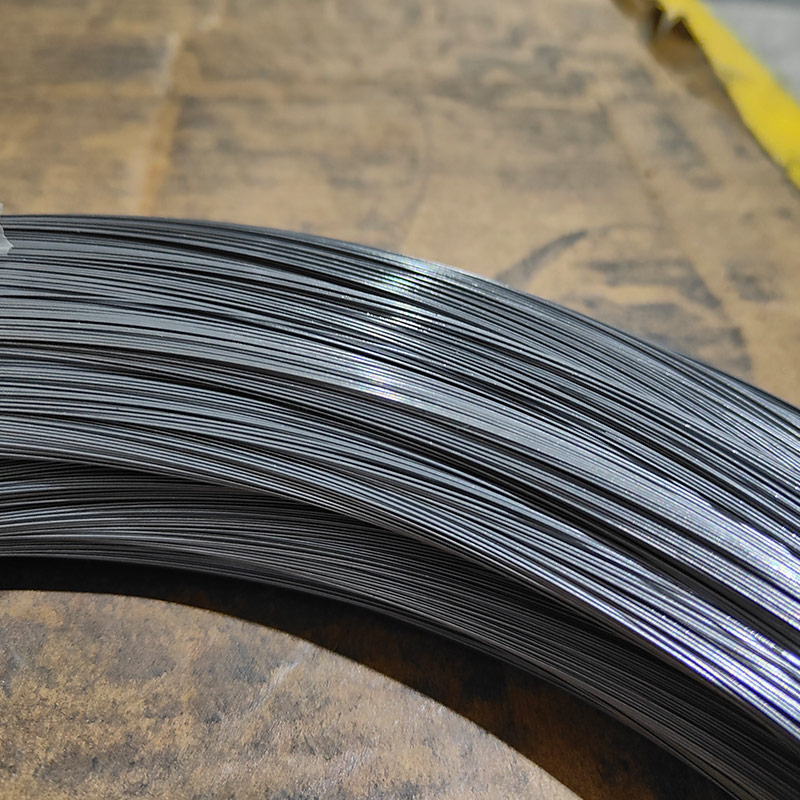

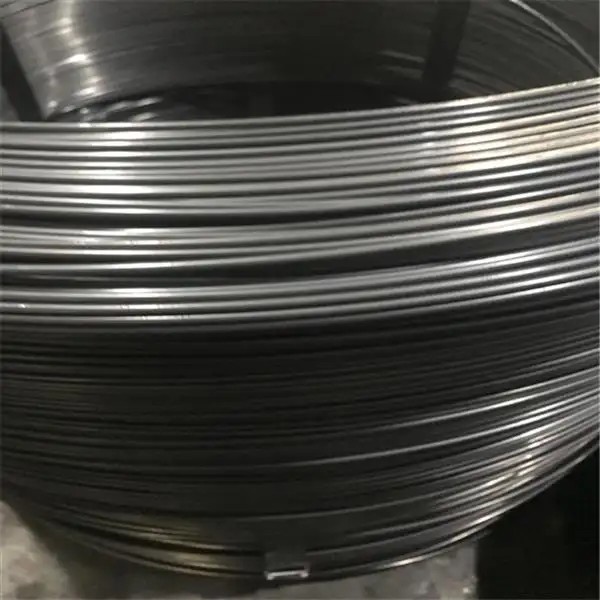

Carbon steel wire is a very important variety of metal products. It uses hot-rolled wire rod as raw material. After the surface preparation process before drawing, the iron oxide scale on the surface of the wire rod is removed and the surface is coated, such as phosphorus. The treated steel wire is then subjected to cold drawing with a certain total compression ratio to obtain steel wires with certain specifications and certain physical properties, including low-carbon, medium-carbon and high-carbon steel wires to meet the needs of different uses. . Carbon steel wire can be sold as a commodity, or can be further processed as a raw material, such as making springs, twisting steel strands, wire ropes or woven wire meshes, etc.

Classification of Carbon Steel Wires

Carbon steel wire (also known as high-strength steel wire) is made of high-quality high-carbon steel wire rod after Soxhlet treatment, pickling, copper plating or phosphating and then cold drawing. The carbon steel wire is made of 80 steel, and its carbon content is 0.7% to 0.9%. Carbon steel wire can be divided into: cold drawn steel wire, stress relief steel wire, scoring steel wire, low relaxation steel wire and galvanized steel wire according to the requirements of deep processing.

MINGP Carbon Steel Wire Performance Test

When the steel wire enters the field, it should be accepted in batches. Each batch is 3t, and each batch is composed of steel wires of the same grade, shape and size, and delivery status. Take one tensile sample from each plate, 5% of each batch but not less than 5 plates, and take one repeated bending sample from each plate. Check the appearance and size of the wire coil by coil. There shall be no cracks, thorns, splits, mechanical damage, iron oxide scale and oil stains on the surface of the steel wire. 10% of the number of coils in each batch of steel wire shall be arbitrarily selected, and no less than 6 coils shall be selected from each end of each coil of steel wire.

The specimens were tested for tensile strength, elongation and bending times. Even if one test piece does not meet the requirements in the inspection result, in addition to the steel wire as unqualified, double the number of test pieces should be taken from the batch of uninspected steel wire coils, and the unqualified items should be re-inspected and re-inspected. As a result, if there is still one test piece unqualified, the batch of steel wire is regarded as unqualified product. The steel wire shall be accepted in batches.